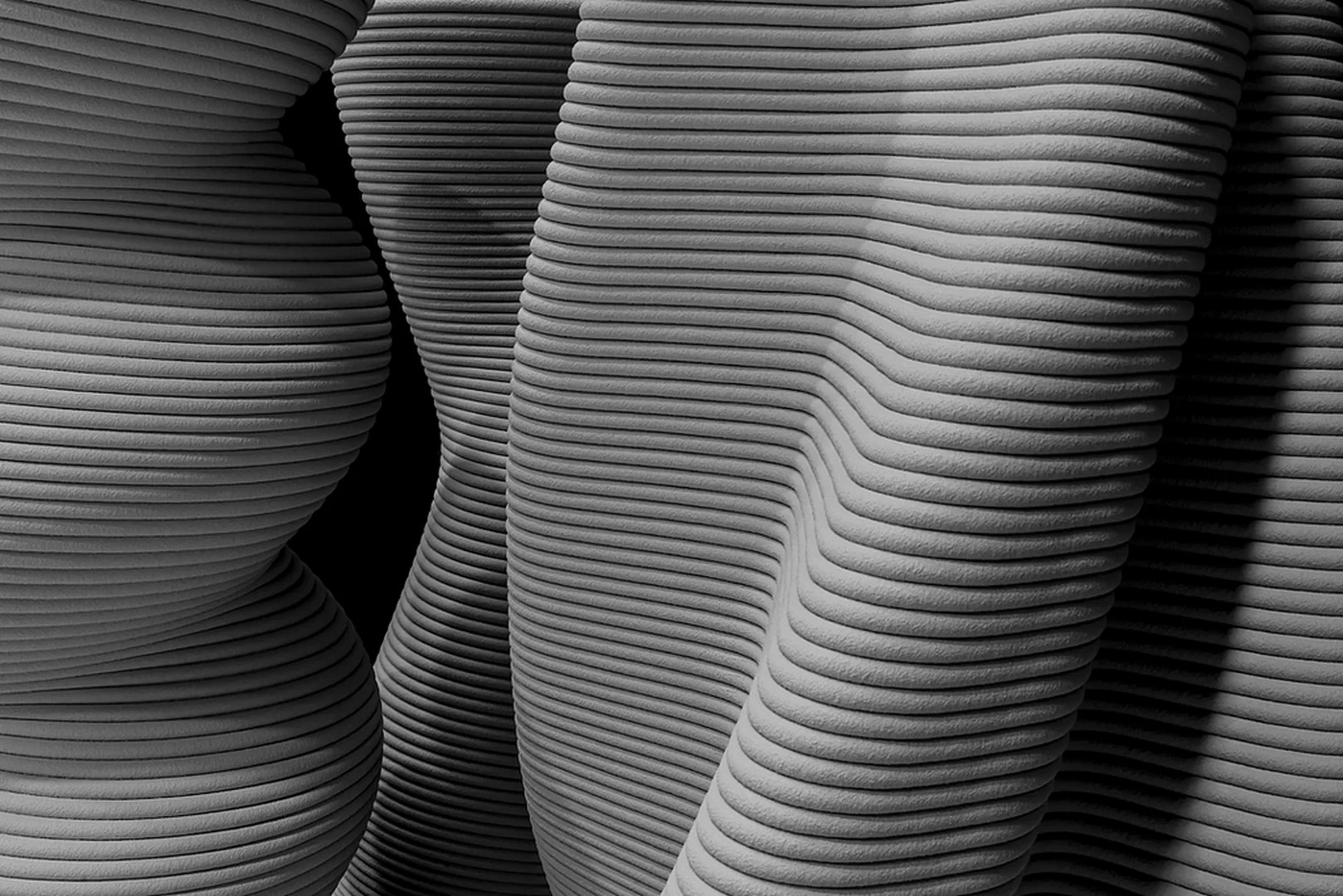

3D concrete printing, also known as cementitious 3D construction printing (3DCP), represents a revolutionary approach to construction that offers unparalleled design flexibility and efficiency. By leveraging additive manufacturing techniques, 3D concrete printing enables the fabrication of custom objects ranging from architectural furniture to large-scale buildings and civil infrastructure. Sika, a leading provider of construction materials and solutions, offers innovative products specifically designed to support the advancement of 3D concrete printing technology.

The Potential of 3D Concrete Printing

The Potential of 3D Concrete Printing

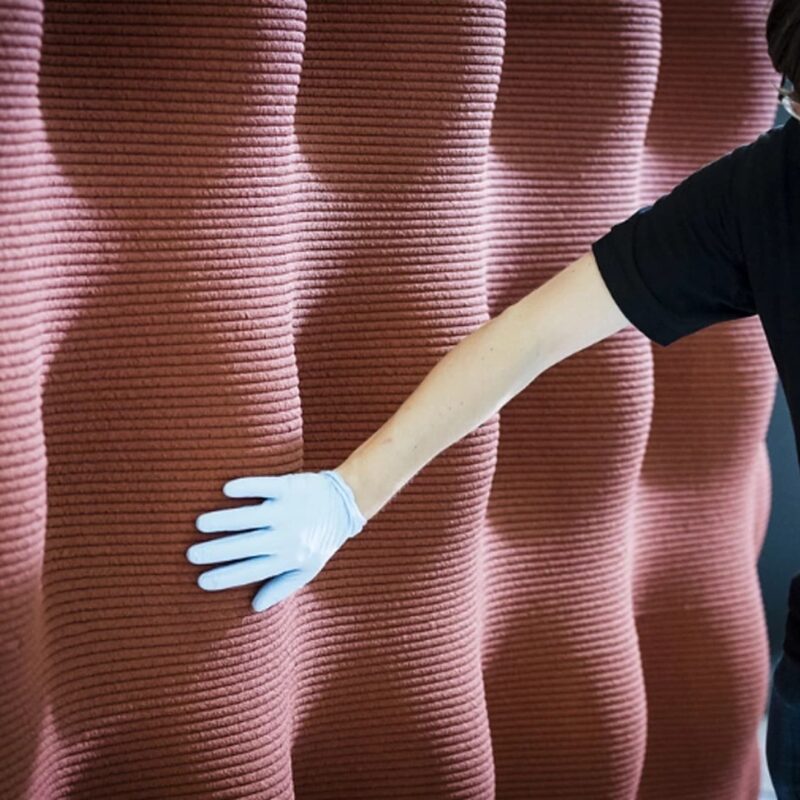

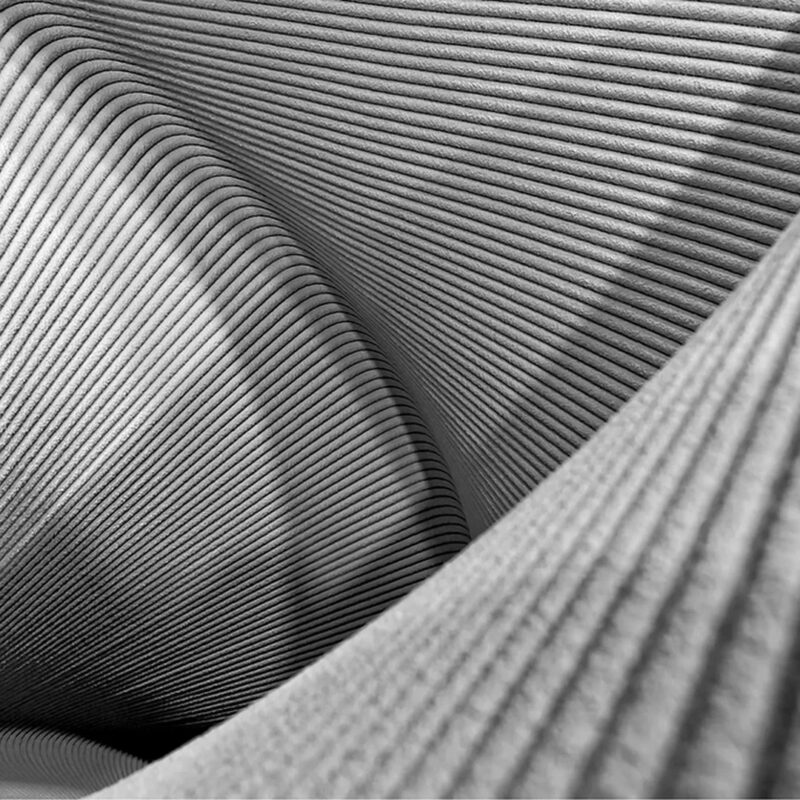

The adoption of digital technology, including 3D concrete printing, is transforming the construction industry by enhancing productivity and offering new possibilities for design and construction. Unlike traditional concrete casting methods, 3D concrete printing allows for the creation of complex shapes and structures that were previously unattainable. With Sika’s Sikacrete® 3D material solutions, concrete can be precisely and rapidly printed according to project specifications, opening up a world of creative opportunities for architects, engineers, and contractors.

Understanding the Process

The process of 3D concrete printing involves several key steps:

- Mounting the Print Head/Nozzle: A print head or nozzle is mounted onto a robot arm or gantry, serving as the tool for extruding the concrete mix.

- Mixing and Pumping: The components of the concrete mix are mixed and pumped into the print head or nozzle through a hose pipe.

- Extrusion: The mix is extruded onto the printing surface in layers, gradually building up the desired structure.

- Optional Additions: Additions or admixtures can be introduced to the mix to modify its properties, such as setting time or strength.

Equipment and Solutions

To facilitate the 3D concrete printing process, several pieces of equipment and materials are required:

- Positive Action Pan Mixer: Used for mixing cementitious materials.

- Pump: Conveys the freshly mixed material continuously to the print head or nozzle.

- Robot Arm or Gantry: Includes control software for precise movement and positioning.

- Print Head/Nozzle: Extrudes the concrete mix onto the printing surface.

- Slicing Software: Translates a 3D computer model into a machine program for printing.

Sika offers comprehensive solutions tailored to the needs of 3D concrete printing projects, including Sikacrete® 3D materials, technical support, and compatible products for enhancing the printing process and the quality of the final product.

Sika offers comprehensive solutions tailored to the needs of 3D concrete printing projects, including Sikacrete® 3D materials, technical support, and compatible products for enhancing the printing process and the quality of the final product.

Advantages of Sika’s 3D Concrete Printing Solutions

Sika’s 3D concrete printing solutions offer numerous benefits:

- Technical Support: Access to expertise and assistance from local Sika organizations with knowledge in cementitious technology and 3DCP applications.

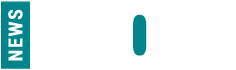

- High Quality: Sika materials deliver excellent performance, with small grain sizes for a smooth finish and optional colors available.

- Increased Productivity: Accelerated products allow for faster printing and stacking of layers, resulting in improved output.

- Add-Ons: A range of Sika products can enhance the durability, aesthetics, and functionality of printed objects.

Compatible Solutions and Future Developments

Sika provides a range of compatible products designed to complement 3D concrete printing projects, including concrete admixtures, filling materials, sealants, and bonding agents. Moreover, Sika actively collaborates with partners to develop materials that work seamlessly with different types of 3D concrete printing equipment, further advancing the capabilities of this transformative technology.